The demand for smaller, lighter, and more efficient electronics is growing fast. Industries like electric vehicles (EVs), renewable energy, and aerospace need high-performance power solutions. Silicon carbide power modules (SiC modules) are stepping up to meet these needs.

Unlike traditional silicon-based components, silicon carbide power modules offer higher efficiency, better thermal performance, and reduced size. But are they truly the key to compact, lightweight electronics? Let’s explore.

Why Silicon Carbide Power Modules Stand Out

Silicon carbide power modules outperform traditional silicon in several ways:

- Higher Efficiency – SiC modules lose less energy as heat, improving power conversion.

- Smaller Size – They handle higher voltages in a smaller footprint.

- Lighter Weight – Less cooling is needed, reducing overall system weight.

- Better Thermal Performance – They run cooler even under high power loads.

These advantages make them ideal for industries where space and weight matter, like EVs and aerospace.

SiC Modules in Automotive: A Game Changer

The automotive SiC module market is booming. Major SiC module manufacturers like Wolfspeed, Infineon, and Shenhuaying Semiconductor are supplying parts for EVs. Why? Because SiC power module automotive applications benefit from:

- Faster charging – SiC enables ultra-fast EV chargers.

- Longer range – More efficient power use means fewer battery drains.

- Smaller inverters – Less bulky components free up space in vehicles.

As EV adoption grows, the SiC module market will expand even further.

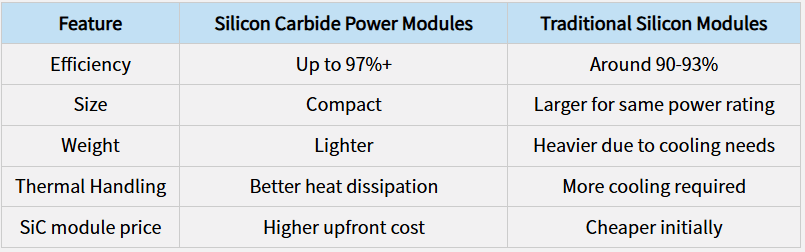

SiC Modules vs. Traditional Silicon: A Clear Winner?

While silicon carbide power modules cost more, their long-term savings in efficiency and space make them worth it.

Challenges in Adopting SiC Power Modules

Despite their benefits, there are hurdles:

- Higher Cost – The SiC module price is still higher than silicon, though costs are dropping.

- Manufacturing Complexity – Producing defect-free SiC wafers is harder.

- Design Challenges – Engineers must adapt circuits for SiC’s high-speed switching.

However, as technology improves, these challenges will lessen.

The Future of Silicon Carbide Power Modules

The SiC module market is set for massive growth. Experts predict a $6 billion+ market by 2030, driven by EVs, solar power, and industrial applications.

Key trends to watch:

- More affordable SiC modules as production scales up.

- New players entering the SiC module manufacturers space.

- Wider use in consumer electronics for ultra-fast charging.

Conclusion

Silicon carbide power modules are transforming electronics. Their ability to deliver high efficiency in smaller, lighter packages makes them ideal for EVs, renewable energy, and beyond. While cost remains a barrier, the long-term benefits outweigh it. As technology advances, we’ll see even wider adoption of SiC power modules, making them a cornerstone of next-gen electronics.