Less Energy

More Efficiency

- Products

- IPM Modules

- IGBT Modules

- IGBT Discretes

- IGBT Chips

- SiC

- FRD(MUR)

- Bridge Rectifier

- Application

- Energy Vehicle

- Home Appliance

- Renewable Energy

- Industrial Equipment

- Data Centers

- …

- Products

- IPM Modules

- IGBT Modules

- IGBT Discretes

- IGBT Chips

- SiC

- FRD(MUR)

- Bridge Rectifier

- Application

- Energy Vehicle

- Home Appliance

- Renewable Energy

- Industrial Equipment

- Data Centers

Less Energy

More Efficiency

- Products

- IPM Modules

- IGBT Modules

- IGBT Discretes

- IGBT Chips

- SiC

- FRD(MUR)

- Bridge Rectifier

- Application

- Energy Vehicle

- Home Appliance

- Renewable Energy

- Industrial Equipment

- Data Centers

- …

- Products

- IPM Modules

- IGBT Modules

- IGBT Discretes

- IGBT Chips

- SiC

- FRD(MUR)

- Bridge Rectifier

- Application

- Energy Vehicle

- Home Appliance

- Renewable Energy

- Industrial Equipment

- Data Centers

SiC Module

SHYSEMI has completed the design of its 3300 V / 800 A ultra-high-voltage SiC module wafers.

Why choose SHYEMI's SiC Module?

SHYSEMI's SiC modules are primarily used in new energy vehicles and photovoltaic energy storage systems. The company's technology in the electric vehicle sector is well-established, with long-term partnerships in place with leading manufacturers such as Volkswagen, GAC, and BAIC.

In photovoltaic energy storage applications, the modules also deliver substantial gains in energy efficiency.SHYSEMI's silicon carbide power devices feature a breakdown voltage of up to 200 kV and an operating temperature of up to 600°C. Thanks to their very low on-state resistance and suitability for high-voltage, high-temperature, and high-frequency environments, these SiC-based power switches can reduce switching-related power losses by more than 80% compared to traditional silicon-based devices, while also reducing volume and weight by approximately 40%. These advantages are poised to significantly influence future grid infrastructure and energy strategy adjustments.

Package List

EconoDUAL

Copper-clad substrate. Thermal cycling. Power cycling.

HPD

Electric vehicle. Inverter market.

DCM

Dual-sided heat dissipation.

Thermal resistance reduced 50%.

Econo2

Optimized thermal resistance. Temperature sensing. Current sensing.

TPAK

Compact in size. Applications such as OBC and DC-DC converters.

SOT-227

Moderate chip design. Mature system design

EconoDUAL Applications:

EconoDUAL boasts excellent reliability and robustness. SHYSEMI has optimized the internal bus structure, resulting in relatively low parasitic inductances in the power circuit and gate circuit, which helps to reduce switching overvoltage and oscillations and improve system stability.

- Synchronous Rectification of SMPS

- Hard Switching

- High-speed Circuits

- DC/DC in Telecommunications

- Industrial Fields

Features:

- High-speed Power Switching

- Enhanced Body Diode DV/DT Capability

- Enhanced Avalanche Strength

HPD Applications:

SHYSEMI’s HPD products meet stringent automotive industry standards such as AEC-Q101 and AQG-324. They offer high power cycling and temperature cycling capabilities, ensuring a lifespan of up to 15 years or tens of thousands of kilometers. Long-term supply agreements have been signed with leading automotive brands, including GAC, Dongfeng, Great Wall, and BAIC.

- Automotive Applications

- Hybrid Electrical Vehicles (H)EV

- Motor Drive

- Commercial Agriculture Vehicles

Features:

- VDSS=1200V

- IDnom=400A

- New Semiconductor Material-Silicon Carbide Low RDSon

- Low Switching Losses

- Low Qg and Crss

- Low Inductive Design <10nH

- Tvjop=150°C

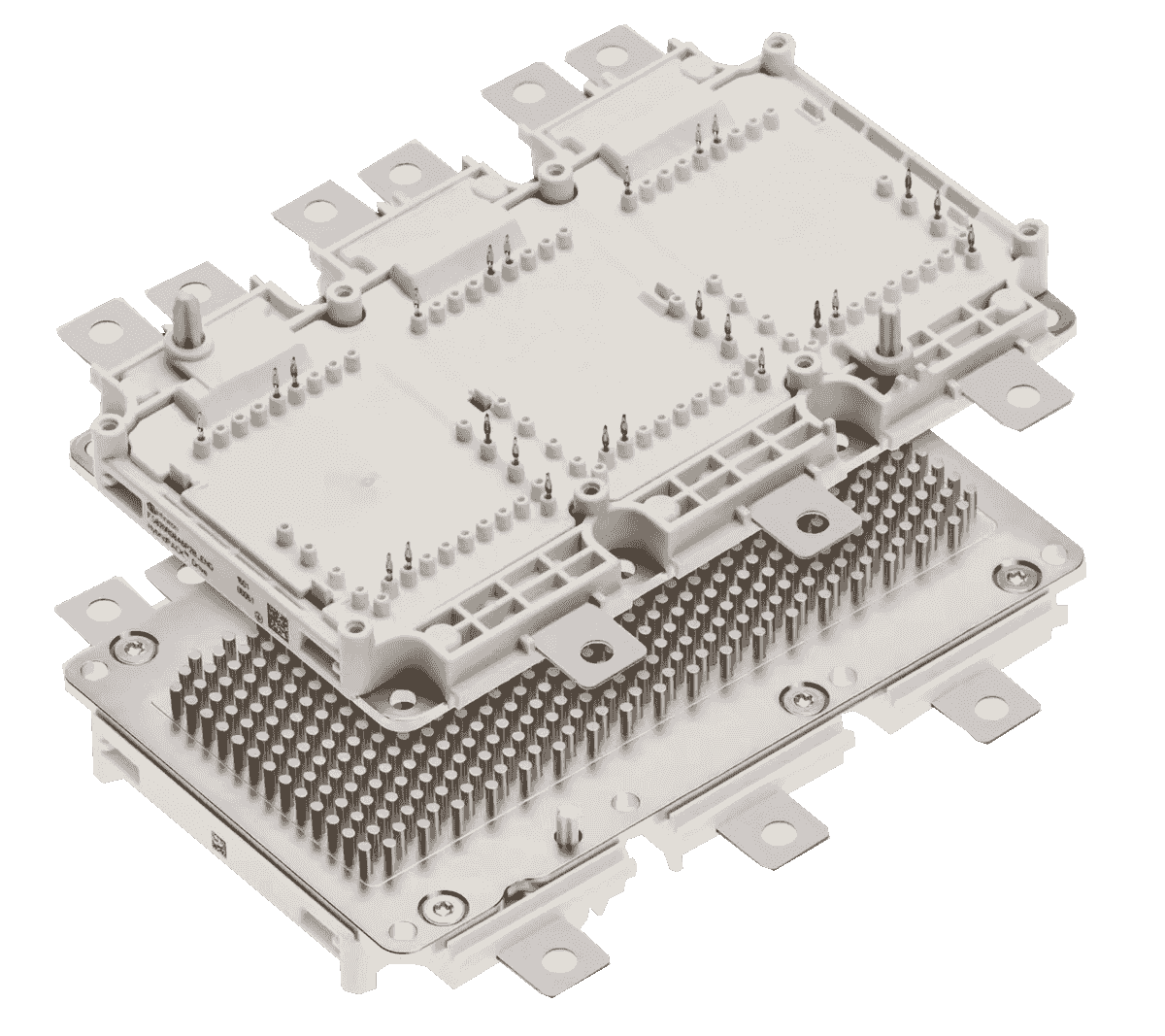

DCM Applications:

The DCM (Direct Cooled Module) packaging represents the pinnacle of dual-side cooling technology, achieving optimal power density and thermal dissipation efficiency. Compared to HPD and other single-side cooling modules at equivalent output power, the DCM reduces volume and weight by over 30%, making it a key solution for the high integration and miniaturization of electric drive systems. SHYSEMI’s DCM is designed primarily for high-end electric vehicles, high-performance models, fuel cell vehicles, and related air compressor drives.

- Automotive Applications

- Hybrid Electrical Vehicles (H)EV

- Motor Drive

- Commercial Agriculture Vehicles

Features:

- Low Switching Losses

- Low Inductive Design ≤6.6nH

- Low Qg and Crss

- High Performance Si3N4 Ceramic

- Direct Cooled PinFin Base Plate

- Low Inductive Design <10nH

- Hight Tg EMC Transfer Molding

- Copper wire bonding

- Ag sintering

Econo2 Applications:

While conventional Econo modules predominantly utilize fourth-generation IGBT technology, SHYSEMI's offerings, which also employ this generation, achieve a notable advancement: a voltage class upgrade from 1200V to 1700V within an equivalent die size. Furthermore, these devices are fabricated at a top-tier wafer fab within the globally recognized Huahong Group, benefiting from a stringent quality control regime that ensures superior product reliability.

- Solar Inverter

- 3-Phase PFC

- UPS and SMPS

- Regen Drives

- Motor Drive

- Induction Heating

Features:

- Ultra Low Loss

- High-Frequency Operation

- Zero Reverse Recovery Current from Diode

- Zero Turn-off Tail Current from MOSFET

- Normally-off, Fail-safe Device Operation

- Easy of Paralleling

- Copper Baseplate and Aluminum Nitride Insulator

TPAK Applications:

Designed for SiC MOSFETs and high-frequency use, SHYSEMI's TPAK is a compact, automotive-grade power package. It employs a lead-frame and copper-clip design to minimize source inductance. This low-inductance architecture unlocks the full high-speed switching potential of SiC, allowing frequencies to reach hundreds of kilohertz. The resulting increase in switching frequency paves the way for a significant miniaturization of external passive components, such as inductors and capacitors.

- Very low RDS(on) over the entire temperature range

- High speed switching performances

- Very fast and robust intrinsic body diode

- Source sensing pin for increased efficiency

- Main inverter (electric traction)

Features:

- Low drain-source on-resistance: RDS(ON) = 8.9 mΩ (typ.)

- Easy to control Gate switching

- Enhancement mode: Vth = 1.8 to 4.0V

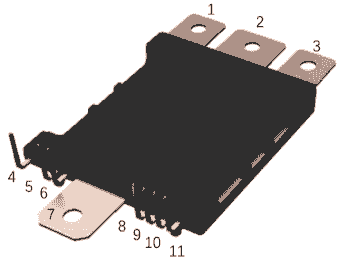

SOT-227 Applications:

SHYSEMI's SOT-227 package features a military-grade rugged structure. Internally, it employs a Direct Bonded Copper (DBC) substrate and anti-fatigue soldering technology, endowing it with power cycling capabilities that far exceed those of conventional packages. Its typical lifespan can exceed 100,000 temperature cycles, ensuring long-term stable operation even in harsh industrial environments.

Furthermore, the package utilizes a "stacked busbar" design, with power terminals (DC+, DC-, AC output) arranged in parallel. This configuration enables loop inductance as low as 10nH, a critical feature for modern high-speed IGBTs and SiC MOSFETs as it effectively suppresses switching overvoltage and oscillations.

- Welder CVT

- UPS

- DC Charging

- High Frequency Output Rectifier

Features:

- Almost no switching loss

- Negligible reverse recovery

- High surge current capabilit

- Higher switching frequency

- System efficiency improvement

- Positive Temperature Coefficient

- Temperature-Independent Switching

- Low heat dissipation requirements

- RoHS Halogen-free/Rohs compliant

SHYSEMI is striving to become a world-leading semiconductor supplier.