In power electronics systems, overcurrent and short-circuit protection for IGBTs (Insulated Gate Bipolar Transistors) is crucial. Proper protection circuit design not only effectively extends the lifespan of IGBT modules but also significantly enhances system reliability and safety. As a leading domestic semiconductor solutions provider, SHYSEMI is committed to delivering high-performance IGBT drive and protection solutions for a wide range of applications, including industrial frequency converters, new energy systems, and electric vehicles.

1.The Necessity of Overcurrent and Short-Circuit Protection

When a short-circuit fault occurs, the IGBT's collector current increases rapidly, exceeding the set value and causing a sharp rise in the collector-emitter voltage (Vce). Although some IGBTs possess a certain short-circuit withstand capability and can tolerate overcurrent for short periods, prolonged exposure to high voltage and high current loads still seriously threatens device safety. Generally, the short-circuit duration an IGBT can withstand is extremely short, typically ranging from a few microseconds to tens of microseconds, depending on its saturation voltage drop and the magnitude of the short-circuit current.

Excessive short-circuit current not only significantly reduces the IGBT's effective withstand time but also causes overvoltage across parasitic inductances during the turn-off process due to a high current change rate (di/dt). This overvoltage can lead to latch-up or even permanent damage of the IGBT. Therefore, a fast and reliable overcurrent protection circuit is indispensable in system design.

2.Mainstream Protection Strategies: Soft Gate Voltage Reduction and Soft Turn-Off

To suppress turn-off overvoltage and reduce electromagnetic interference, a comprehensive protection approach combining soft gate voltage reduction and soft turn-off is widely adopted. The core process is as follows:

- Upon detecting an overcurrent signal, the gate voltage reduction phase is initiated. By lowering the gate voltage, the short-circuit current amplitude is limited, thereby extending the IGBT's short-circuit withstand duration.

- After gate voltage reduction, a brief delay is implemented to verify the fault. If the fault disappears during this period, the gate voltage automatically recovers. If the fault persists, the soft turn-off process is activated, gradually reducing the gate voltage below 0V to achieve safe shutdown of the IGBT.

This method suppresses voltage spikes and current variation rates by progressively reducing the current amplitude and slowing down the turn-off process, ensuring the IGBT always operates within its Safe Operating Area (SOA).

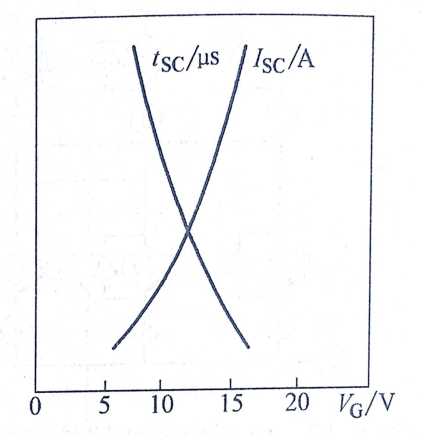

3.Relationship Between Gate Voltage and Short-Circuit Characteristics

The IGBT short-circuit current (Isc) is closely related to the gate-emitter voltage (Vge): a higher Vge results in a larger short-circuit current. Therefore, rapidly and gradually reducing Vge during a short-circuit or transient overcurrent can significantly suppress the current amplitude and reduce di/dt during turn-off. Common integrated driver circuits such as the EXB841 and M579xx series, as well as the IGBT driver solutions provided by SHYSEMI, feature built-in Vce detection and gate voltage clamping. These circuits automatically limit the gate voltage to around 10V upon detecting desaturation, effectively restricting overcurrent and extending the allowable fault time.

Figure 1. Relationship between IGBT short-circuit withstand time (tsc), short-circuit current (Isc), and gate voltage (Vge).

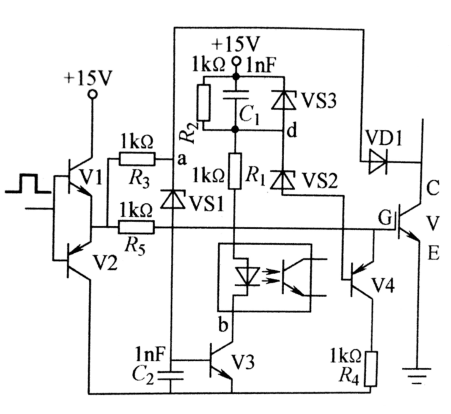

4.Analysis of Classic Slow-Ramp Gate Voltage Reduction Circuit

The slow-ramp gate voltage reduction technique controls the rate of gate voltage decrease to limit the fault current change rate, thereby suppressing voltage stress during turn-off. A typical circuit implementation is as follows:

- When the system detects an overcurrent or short circuit, the Vce voltage increases, triggering the Zener diode breakdown and turning on transistor V3.

- Capacitor C1 is charged slowly through resistor R1. When its voltage reaches approximately 1.4V, transistor V4 begins to conduct, and Vge decreases gradually with the capacitor voltage.

- By appropriately selecting the capacitance value of C1, the rate of Vge reduction can be precisely controlled, effectively suppressing di/dt.

- When the voltage across C1 rises further to the breakdown value of another Zener diode, Vge is clamped at a fixed level, and the slow-ramp gate voltage reduction process ends.

*Figure 1.Circuit for Slowly Lowering Gate Voltage*

If the fault disappears during the delay period, the circuit automatically returns to normal operation, significantly enhancing anti-interference capability and system reliability.

5.Fault Current Reduction

By reducing or limiting high fault currents, especially in short-circuit and low-impedance ground fault scenarios, IGBT power modules can be better protected. In type II short-circuit conditions, high dvCE/dt causes the gate-emitter voltage to rise, resulting in a dynamic short-circuit overcurrent. The amplitude of this short-circuit current can be reduced by clamping the gate-emitter voltage.

In addition to limiting dynamic short-circuit overcurrent, the steady-state short-circuit current can also be reduced by decreasing the gate-emitter voltage. This method reduces power losses in the IGBT module during a short-circuit event. Moreover, since the short-circuit current to be interrupted is relatively small, the overvoltage is also reduced.

The principle is illustrated in Figure 3. This protection technique can limit the steady-state short-circuit current of the IGBT power module to approximately three times the rated current.

*Figure 3. Limiting short-circuit current by reducing gate-emitter voltage.*

6.Technical Advantages of SHYSEMI in IGBT Protection

SHYSEMI's IGBT driver protection solutions offer high integration and reliability, supporting advanced functions such as desaturation detection, soft shutdown, and active Miller clamping. They are suitable for various applications including photovoltaic inverters, motor drives, and UPS systems. Key protection features include:

- Dynamic and steady-state short-circuit current limiting, capably restricting short-circuit current to within three times the rated value;

- Optimized gate voltage reduction rate and soft turn-off trajectory, effectively suppressing voltage spikes and thermal losses;

- Comprehensive fault feedback and self-recovery mechanisms, ensuring continuous and stable system operation.

In summary, well-designed IGBT overcurrent protection circuits are essential for enhancing system robustness. By combining classic circuit structures such as slow gate voltage reduction and soft turn-off with high-performance driver solutions like those provided by SHYSEMI, comprehensive protection for IGBT power modules can be achieved under harsh operating conditions, significantly improving device longevity and overall system performance.