Less Energy

More Efficiency

- Products

- IPM

- IGBT Modules

- IGBT Discretes

- IGBT Chips

- SiC

- FRD(MUR)

- Bridge Rectifier

- Application

- Energy Vehicle

- Home Appliance

- Renewable Energy

- Industrial Equipment

- Data Centers

- …

- Products

- IPM

- IGBT Modules

- IGBT Discretes

- IGBT Chips

- SiC

- FRD(MUR)

- Bridge Rectifier

- Application

- Energy Vehicle

- Home Appliance

- Renewable Energy

- Industrial Equipment

- Data Centers

Less Energy

More Efficiency

- Products

- IPM

- IGBT Modules

- IGBT Discretes

- IGBT Chips

- SiC

- FRD(MUR)

- Bridge Rectifier

- Application

- Energy Vehicle

- Home Appliance

- Renewable Energy

- Industrial Equipment

- Data Centers

- …

- Products

- IPM

- IGBT Modules

- IGBT Discretes

- IGBT Chips

- SiC

- FRD(MUR)

- Bridge Rectifier

- Application

- Energy Vehicle

- Home Appliance

- Renewable Energy

- Industrial Equipment

- Data Centers

Key Autonomous Technologies

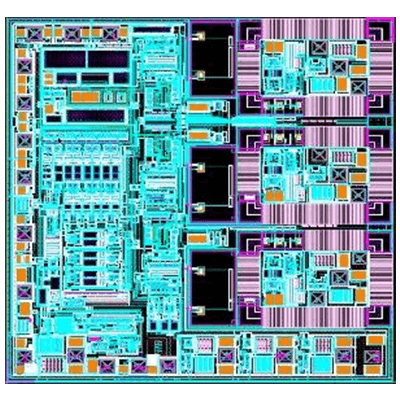

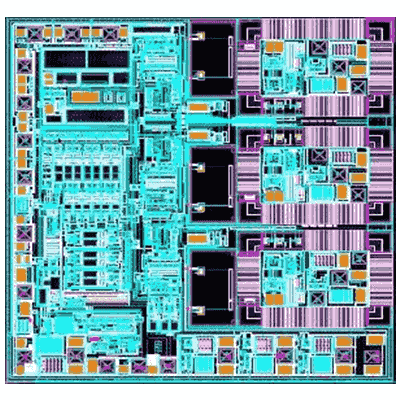

- IGBT & CHIP

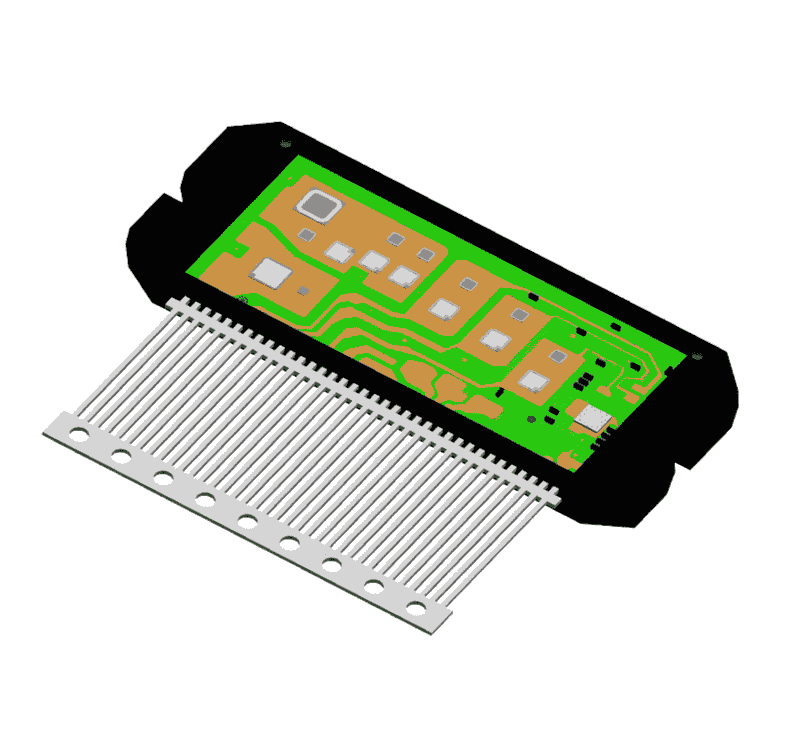

Technical Advantages Of IPM Products

The IPM products of SHYSEMI have the following four advantages: advanced technology IGBT, integrated multiple functions Drive IC, high insulation IMS substrate, and high-quality packaging materials.

SYIM756-SFT: SHYSEMI's Flagship IPM Solution

- Proprietary 7-channel HVIC with enhanced noise immunity.

- Independent Trench FS IGBT for inverter/PFC PWM applications.

- IMS substrate withstands >6000V insulation voltage.

- Japanese low-CTE package: 1.7W/m·K thermal conductivity, Tg ≥180°C.

Four IPM Technologies

The IPM products of SHYSEMI have the following four advantages: advanced technology IGBT, integrated multiple functions Drive IC, high insulation IMS substrate, and high-quality packaging materials.

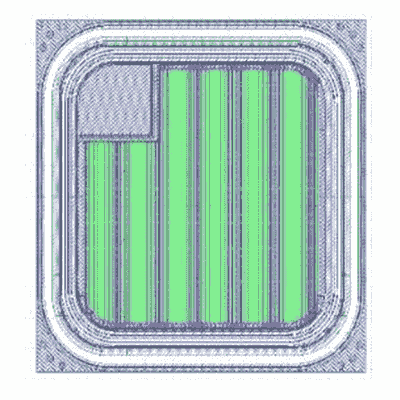

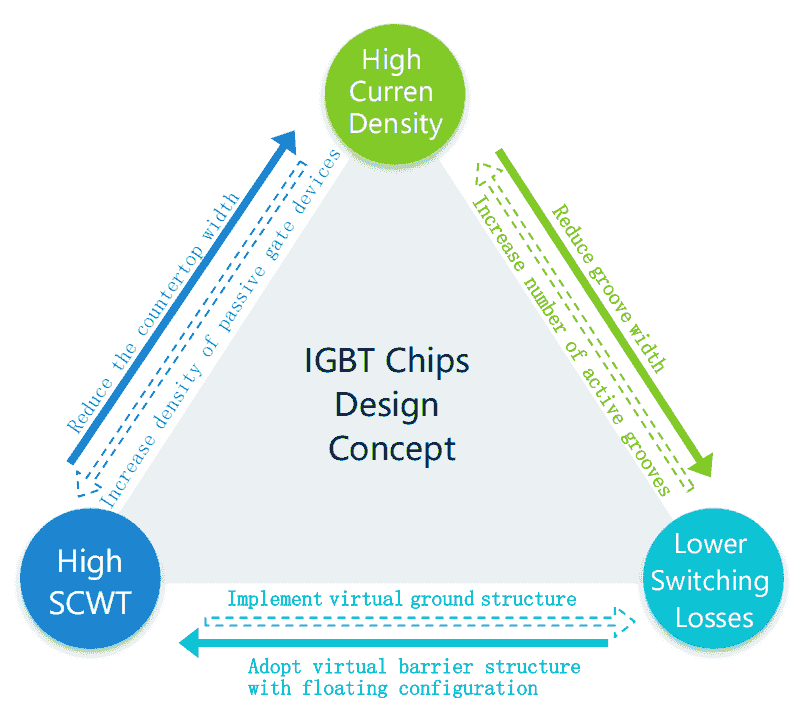

IGBT

- Design of grooved strip grating

- Field board and lateral variable doping terminal

- Field cutoff technology

- Design switch speed matching for inverter and PFC PWM frequencies separately

Drive IC

- Integrated bootstrap circuit

- Integrated PFC driver circuit

- Integrated PFC protection circuit

- Detection port anti-interference design

- Good match with independently developed IGBT

IMS

- High thermal resistance, high TC passivation layer material

- Anodic oxidation process

- Low EMl busbar design

- Design of anti-interferencegrounding wire

- Anti layering technology

EMC

- Various shapes and particle sizes of Al2O3 filling

- High TG plastic sealing material

- Matching of Linear Thermal

- Expansion Coefficient with Substrateand Chip Materials

- Techniques for increasing fluidityand reducing viscosity

Technical Advantages Of Chips

SHYSEMI's IGBT chips are independently designed using the 6th generation Trench Field process. They have developed 1200V (75A-300A) chips and corresponding FRD series products, as well as 1700V (150A/200A) series products. The performance of these products ranks at the forefront of the industry, and the 1700V series has reached the leading level in China.

SHYSEMI’s Core Strengths Of Chips

- Tape-out conducted at the world’s third-largest wafer fab (Huahong Group).

- Chips utilize SHYSEMI's proprietary 6th-generation Trench Field technology.

- Enables operating voltage increase from 1200V to 1700V within the same die size.

- Vcesat coefficient is notably lower than domestic counterparts.

- Wafer-level CP test data provided.

- Supports customer-customized chip development.

IPM Reliability Analysis Report

Product Model: SYIM15S60, Batch Number: S240821007-0-1-1, passed all the tests.

SHYSEMI vs. Infineon

After we compared the test data of SHYSEMI's chips with that of Infineon, we found that many of the data were on par with the top brands in this industry. Therefore, SHYSEI's chips will be an excellent alternative product.

For More Information or to Get a Product Quotation, Please Send Us

an Email and We Will Contact You as Soon as Possible

We respect the privacy of our customers and keep all customer data secure.

SHYSEMI is striving to become a world-leading semiconductor supplier.