Table of Contents:

● The Central Role of Traction Inverters in Electric Vehicles

● Key Design Considerations

● Technical Architecture and Design Frameworks

● Critical Power Components and EliteSiC Solutions

● IGBT Technology: The Enduring Cornerstone of EV Innovation

Keywords: Traction Inverter, Electric Vehicle (EV), Hybrid Electric Vehicle (HEV), Silicon Carbide (SiC), IGBT, PWM Signals, EliteSiC Solutions, B6S Power Module, Narrow Mesa Field Stop

1. The Core Role of Traction Inverters in Electric Vehicles

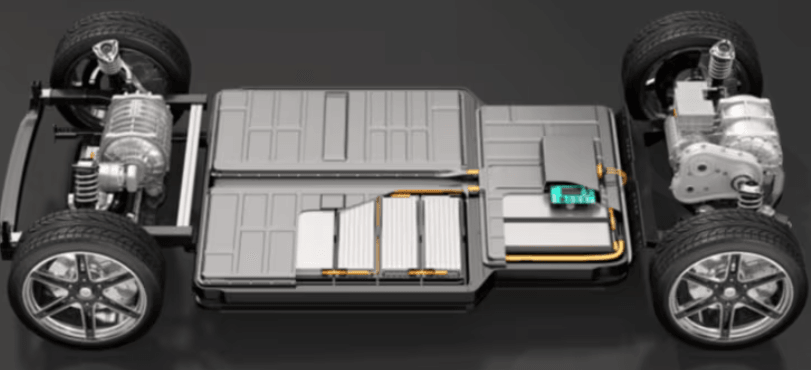

In pure electric vehicles (EVs), the traction inverter serves as the essential interface between the high-voltage DC battery and the AC traction motor. It converts the stored DC energy into precise, high-frequency AC waveforms, enabling torque generation and acceleration control.

This DC-AC conversion makes the traction inverter a core component of every EV drivetrain — directly responsible for propelling the vehicle and defining its overall performance and efficiency.

Most current EVs and hybrid electric vehicles (HEVs) are still based on IGBT technology, while the emergence of silicon carbide (SiC) devices has introduced new possibilities for improved efficiency, thermal management, and power density.

2.Key Design Considerations for Traction Inverters

- Conversion efficiency and driving range

- Peak power and vehicle performance

- The growing demand for SiC technology

- Balancing reliability and power density

2.1 Conversion Efficiency and Driving Range

Efficiency is one of the most critical design parameters in a traction inverter. Higher DC–AC conversion efficiency directly translates into longer driving range for a given battery capacity.

A highly efficient inverter also generates less heat, reducing the load on the vehicle’s thermal management system and enabling a more compact, lightweight design.

2.2 Peak Power and Performance Output

Peak power defines the dynamic behavior of an EV — particularly torque output and acceleration capability.

While efficiency determines how far the car can go, peak power determines how fast it can move. Together, these two parameters define the EV’s overall driving experience and performance envelope.

2.3 The Rising Demand for SiC Technology

As EVs transition toward 800 V battery architectures, traction inverters have become the largest single driver of SiC device adoption in the automotive sector.

Compared with IGBT-based systems, SiC MOSFETs deliver superior performance at higher voltages, allowing greater efficiency, reduced switching losses, and compact inverter designs.

2.4 Reliability vs. Power Density

While increasing power density is a key design objective, reliability remains equally — if not more — important.

Engineers can often mitigate performance bottlenecks, but unexpected failures or downtime can have severe operational consequences. For automotive applications, long-term reliability is paramount.

3.Traction Inverter Architecture and System Design

- Two primary drive architectures

- Power stage: the heart of the traction inverter

3.1 Drive Architecture: Direct vs. Differential Drive

EV traction architectures vary based on how the motor connects to the wheels: either through a direct-drive or differential-drive configuration.

Direct-Drive Architecture:

Achieves higher operational efficiency

Requires minimal mechanical maintenance

Typically used in low-speed, high-torque applications

Differential-Drive Architecture:

Enables higher motor speeds and improved power density

Requires periodic mechanical maintenance

Involves some transmission losses

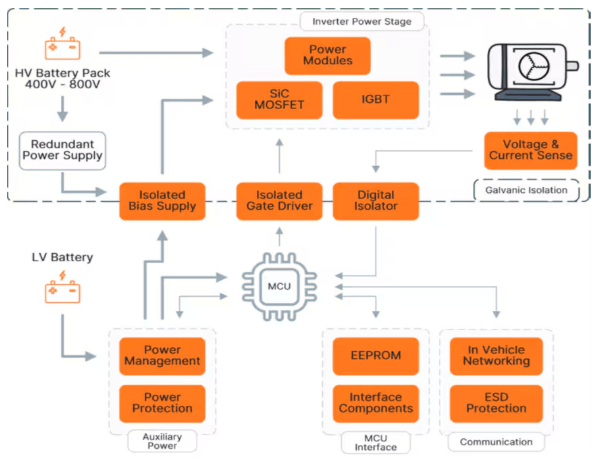

3.2 Power Stage: The Core of the Inverter

A traction inverter’s power stage is more than a set of MOSFETs — it integrates protection, control, and monitoring circuitry to prevent system-level failures.

Power Stage Composition:

High-power semiconductor switches: IGBTs or SiC MOSFET power modules

Controlled via power management ICs, microcontrollers, or both

Real-time monitoring of voltage, current, and temperature.

3.3 Control Operation

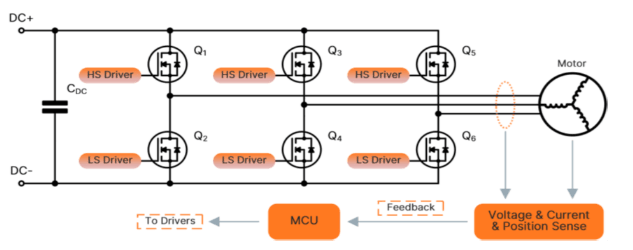

The MCU generates base PWM signals

Isolated gate drivers amplify and condition these signals

Sufficient gate charge is delivered to switch the power devices

Real-time feedback (voltage, current, rotor position) adjusts the modulation strategy.

4. MOSFETs — The Heart of the Power Sta

ge

- The Role of MOSFETs

- EliteSiC Power Solutions by SHYSEMI

- EliteSiC B2S and B6S Power Module Highlights

4.1 The Role of MOSFE

Ts

Whithin the inverter’s power stage, MOSFETs play a pivotal role in shaping the output current to drive the traction motor.

Through a three-phase bridge topology, they convert DC battery voltage into precise AC waveforms required for efficient motor operation.

4.2 EliteSiC Power Solutions by SHYSEMI

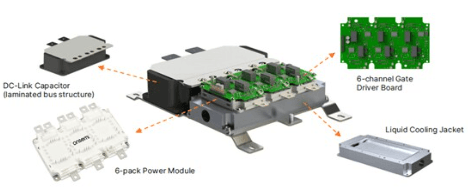

Highly Integrated Design: Single 6-pack module with pin-mounted heatsink

Flexible Design Option: Three half-bridge modules for greater design freedom

Fully Custom Design: Bare-die configuration with six M3e MOSFETs for tailored modules

4.3 EliteSiC B2S and B6S Power Module Highlights

Based on 1200 V SiC M3e technology

B2S: sinterable half-bridge module; B6S: integrated 6-pack module with heatsink

Scalable output range from 160 kW to 400 kW

M3e MOSFET cell pitch reduced by over 60% compared with M1 series

Advanced sintering technology for chip-to-heatsink attachment

5. IGBT Technology: The Enduring Foundation of EV Power Sys

tems

SHYSEMI continues to enhance its IGBT portfolio, introducing innovations such as narrow mesa field-stop IGBT structures that significantly reduce power losses under light-load conditions, thereby improving overall system efficiency in automotive applications.

Evaluation Kits and Development Sup

port

For EV/HEV traction inverter development, SHYSEMI provides two hardware evaluation kits based on VE-Trac IGBT power modules, supporting up to 150 kW operation.

These kits enable customers to evaluate module performance early in the design cycle, with built-in support for double-pulse testing and three-phase inverter motor control.

Intelligent Power Module Applicat

ions

SHYSEMI’s 1200 V / 50 A Intelligent Power Module (IPM) delivers a fully integrated, high-performance inverter output stage for hybrid and electric vehicles.

The module integrates a three-phase IGBT inverter, optimized gate drivers, and comprehensive protection features — ideal for HVAC compressors, high-voltage pumps, and other auxiliary automotive systems.

Conclusion: IGBT — A Cornerstone of EV Electrifica

tion

The Insulated-Gate Bipolar Transistor (IGBT) remains the cornerstone of EV power electronics, combining cost-effectiveness with robust performance and long-term reliability.

Its proven stability under high current loads ensures dependable operation across wide power demand fluctuations — from rapid acceleration to regenerative braking.