The high-frequency high-voltage power supply, as the core equipment of the electrostatic field high-voltage accelerator, has a direct impact on the performance indicators of the accelerator. The closed high-voltage temperature will affect the working stability and reliability of the entire power supply. SHYSEMI believes it is necessary to conduct analysis and research on the components that are most affected by temperature.

The pulse high-voltage modulator high-voltage charging power supply uses an insulated core transformer (Insulated core Transformer, ICT). The voltage transformation principle of ICT is the same as that of a common transformer, both exchanging energy through alternating magnetic fields coupling. ICT adopts a multi-group coil output mode. Through an insulating film, the complete iron core is divided into many small segments. Each small segment is a small power low-voltage transformer for the primary coil. The output voltage of each small power transformer is output through a rectifier circuit, and then the output voltages of each segment are connected in series to obtain a high-voltage output.

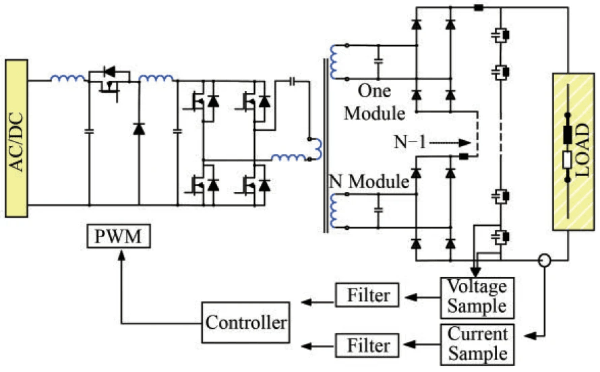

This structure solves the insulation problem of high-voltage transformers, the insulation withstand voltage problem of the primary and secondary coils, the withstand voltage problem of the iron core and the secondary coil, and is conducive to the selection of components on the high-voltage side. The principle diagram of the constant current constant voltage high-voltage charging power supply is shown in Figure 1.

Figure 1 Block Diagram of Constant Current and Constant Voltage High Voltage Charging Power Supply

Based on the Pspice model of the diode, through circuit simulation, the power loss of the diode was analyzed, and the basis for diode selection was proposed.

Experimental verification

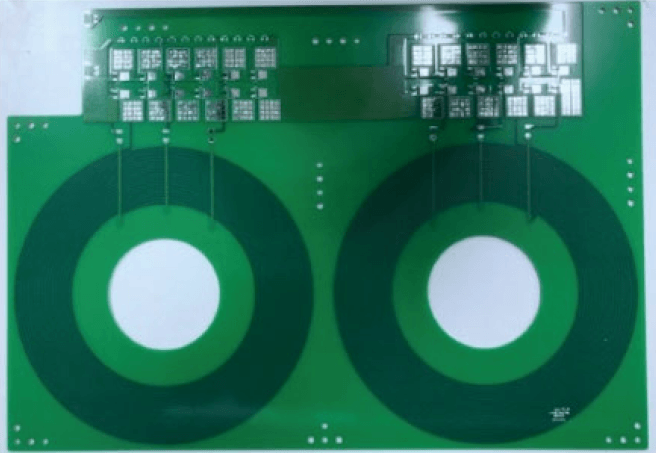

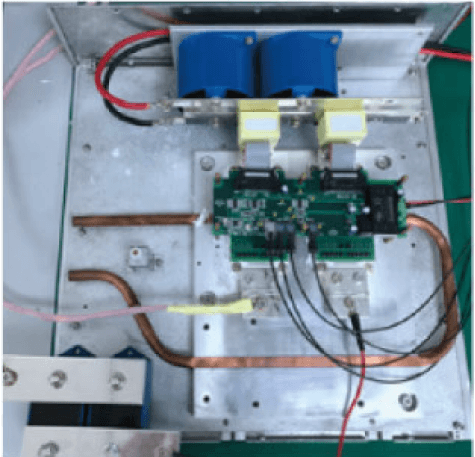

This study designed the main circuit and main power circuit of the constant voltage and constant current high-voltage charging power supply. Due to the multi-layer insulating film structure of the planar insulating core high-voltage transformer, the magnetic core is segmented, and the excitation inductance significantly decreases. To improve the excitation inductance, the primary coil is designed to have 14 turns, while the secondary coil is increased to 16 turns to increase the output voltage. In addition, to optimize the temperature characteristics of the diode, the copper-covered area on the PCB was increased, and each output board contains 6 coil units. The full-bridge converter operates in the LLC resonant state, enabling the rectifying diode to achieve zero current switching (ZCS), effectively improving its working characteristics.

Figure 2 Structure of High Voltage Output Circuit

Figure 3 Single-block high-voltage output circuit board

Figure 4 Full Bridge LLC Conversion Unit

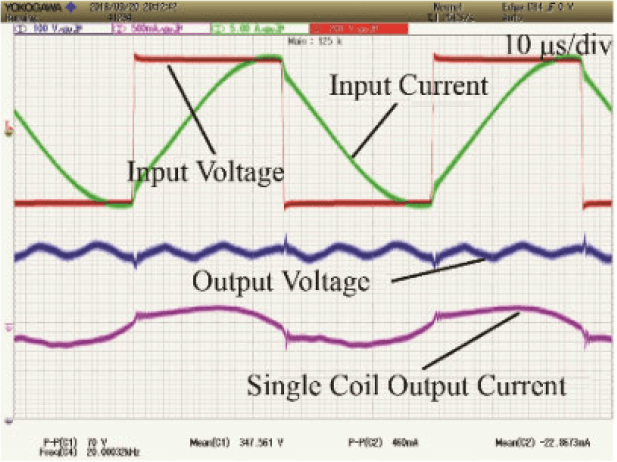

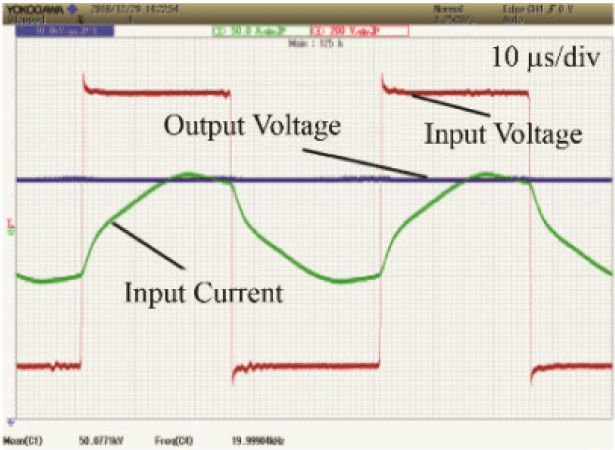

Experimental tests show that in the LLC resonant state, the output current waveform of the SiC diode (Figure 5) has almost no reverse recovery time, thereby reducing power loss. When the high-voltage power supply outputs at 50 kV (Figure 6), each winding unit outputs 600V, and a total of 84 units (336 diodes) are required. Through calculation, the total power loss can be accurately estimated.

Figure 5 Test of Single Board Output Waveform

Figure 6 Output waveform of the high-voltage power supply at 50kV

The measured data show that the input voltage is 556V, the output voltage is 50077V, the input power is 20446W, the load is 135kΩ, and the total loss is 1870W. The specific distribution of losses is as follows:

- LLC resonant power transistor (FF300R12ME4): Switching loss + Reverse recovery loss + On-state loss = 1320.4W

- Filter capacitor equalizing resistor (6.5MΩ): 390W

- Transformer core loss: 35W

- PCB copper foil loss (600m wiring): 40W

- Output current-limiting resistor loss: 10W

The simulation calculated the loss of the diode to be 72.8W, while the measured value was 74.6W. The results were highly consistent. The thermal imaging analysis (Figure 7) showed that the temperature of the transformer remained stable under both loaded and unloaded conditions, verifying the accuracy of the loss calculation. The total loss of the sealed parts (core, coil, and diode) was 159.6W, and thermal equilibrium could be achieved through natural heat dissipation.

Figure 7 Comparison of High Voltage Transformer Temperatures

Conclusion

The use of SiC diodes effectively reduces the heat generation issue in the output section of the insulated core transformer. Due to the limited switching frequency of IGBT, the high-frequency advantage of SiC diodes has not been fully exploited. Future improvements in switching frequency can further optimize performance.