Go Back

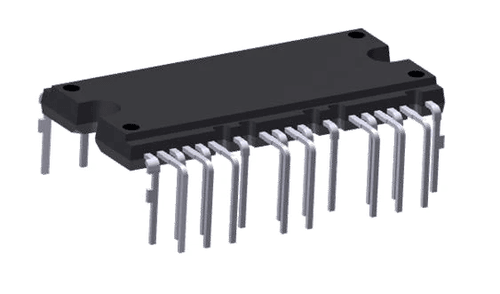

IPM-DIP-25

The DIP-25 refers to a dual in-line package with 25 pins. Its value lies not in miniaturization, but in its outstanding robustness, reliability, and ease of use.

The through-hole solder joints provide a mechanically secure structure capable of enduring strong vibration, mechanical shock, and repeated temperature cycles—conditions that often cause fatigue cracks in surface-mount joints.

This makes the DIP-25 package indispensable in industrial, automotive, and aerospace systems operating under harsh environmental conditions.

Compared with ultra-high-density packages, DIP-25 features lower parasitic capacitance and inductance between pins. Designers benefit from greater routing flexibility on both sides and inner layers of the PCB, allowing for optimized power distribution and signal isolation.

This makes it an ideal choice for noise-sensitive analog circuits or high-voltage digital systems, where stability and long-term reliability are essential.

The through-hole solder joints provide a mechanically secure structure capable of enduring strong vibration, mechanical shock, and repeated temperature cycles—conditions that often cause fatigue cracks in surface-mount joints.

This makes the DIP-25 package indispensable in industrial, automotive, and aerospace systems operating under harsh environmental conditions.

Compared with ultra-high-density packages, DIP-25 features lower parasitic capacitance and inductance between pins. Designers benefit from greater routing flexibility on both sides and inner layers of the PCB, allowing for optimized power distribution and signal isolation.

This makes it an ideal choice for noise-sensitive analog circuits or high-voltage digital systems, where stability and long-term reliability are essential.

More Details

DIP-25 packages are preferred in scenarios where reliability, power capability, and ease of use take precedence over size constraints:

White goods: Air conditioner compressors, fan motors, and inverter systems.

Automotive electronics: Especially in Electronic Control Units (ECUs) of commercial and control vehicles exposed to high vibration and thermal cycling.

Power equipment: High-power linear regulators and Uninterruptible Power Supplies (UPSs).

Industrial control and automation: Programmable Logic Controllers (PLCs), industrial PCs, motor drives, and servo systems.