Go Back

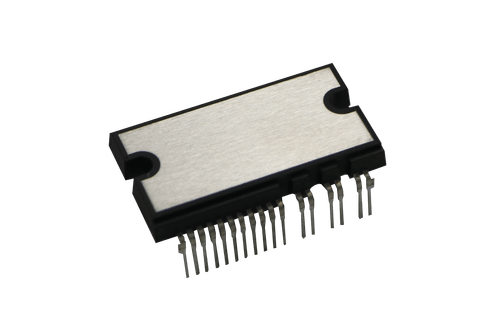

IPM-DIP26

The DIP-26 can be regarded as a reinforced or power-grade dual in-line package.

Its key advantage lies in its wider pin pitch compared with standard DIP or SOP packages. The increased pin spacing directly provides longer creepage and clearance distances, which effectively prevent arcing or short-circuiting between adjacent pins under high-humidity or contaminated conditions.

This design feature greatly improves system reliability and safety in high-voltage environments, making it ideal for applications that must withstand hundreds or even thousands of volts over extended operation periods.

Its key advantage lies in its wider pin pitch compared with standard DIP or SOP packages. The increased pin spacing directly provides longer creepage and clearance distances, which effectively prevent arcing or short-circuiting between adjacent pins under high-humidity or contaminated conditions.

This design feature greatly improves system reliability and safety in high-voltage environments, making it ideal for applications that must withstand hundreds or even thousands of volts over extended operation periods.

More Details

Main Applications:

Solid-State Relays (SSR): This represents the most classic use case for DIP-26. Its high isolation voltage and strong drive capability perfectly meet SSR design requirements.

High-power I/O modules in industrial control systems: Ideal for driving motors, solenoids, and similar loads.

High-voltage power supplies and inverters: Commonly used in driver or sampling circuits.